Engineering Design (ED)

エンジニアリングデザイン(ED)

Biomimicry: the design and production of solutions that are modeled on elements and ideas found in nature.

Biomimicry: the design and production of solutions that are modeled on elements and ideas found in nature.

The students learned this word during the first half of the semester and have been striving to use biomimicry in their Engineering Design class. The task is to create a toy with some surprising element while using biomimicry.

In order to study biomimicry and find inspiration, the students visited the Ishikawa Insect Museum earlier in the semester. There, they saw specimens of insects from around the world and also observed live insects native to Ishikawa. In The Butterfly Garden, students had the chance to walk among the butterflies as they flew around freely. Yuya even made a few butterfly friends who landed on him and would not leave! Some of the students were even brave enough to touch some of the insects as they observed them. They recorded videos in slow motion, sketched drawings, and took pictures. Hopefully, the students are no longer afraid of insects!

Returning to class, students have been working on incorporating biomimicry into the toys they are designing. With various elements of surprise, it’s been fun to see how the students are taking their observations and coming up with new designs and ideas. One group even put a lot of time into gluing and cutting sheets of paper to create their own paper honeycomb. The students are finishing up their prototypes this week and I can’t wait to see how their ideas turned out!

on him and would not leave! Some of the students were even brave enough to touch some of the insects as they observed them. They recorded videos in slow motion, sketched drawings, and took pictures. Hopefully, the students are no longer afraid of insects!

Anne Isobel Tan

2019年1月28日 バイオミミックリー

バイオミミックリー:自然界に見られる生態やアイデアを参考にして、デザインや解決法を生み出すこと。

今学期の前半、学生たちはこの言葉を習ってからバイオミミックリーをエンジニアリングデザインの授業で取り入れようと奮闘しています。課題はバイオミミックリーを活用してサプライズ要素のあるオモチャを作ることです。

バイオミミックリーの発想を得るために、学生たちは石川県ふれあい昆虫館へ出かけました。そこでは、世界中の昆虫の標本や、石川県に住む昆虫を実際に見て触れることができます。チョウの園では、自由に飛び回る蝶々の中を歩き回ることもできます。湧也さんにいたっては、体にとまってもまったく逃げないほど蝶と仲良くなりました!勇気のある学生は見るだけでなく、実際に昆虫を触って観察していました。その他にも、スローモーション撮影をしたり、スケッチをしたり、写真を撮っていました。昆虫と触れ合って、愛着が湧いたかもしれませんね。

教室に戻ってからは、学生はバイオミミックリーをオモチャに取り入れるデザイン作りをしました。サプライズ要素と一口に言っても色々な形があるので、学生がそれぞれ観察した内容を活かした新しいデザインやアイデアを生み出すのを見るのが面白かったです。中には紙を切り貼りして蜂の巣を作った学生もいました。今週でプロトタイプは完成予定なので、どのようにアイデアが形になるのか見るのが楽しみです!

アン・イソベル・タン

Biomimicry: the design and production of solutions that are modeled on elements and ideas found in nature.

Biomimicry: the design and production of solutions that are modeled on elements and ideas found in nature.

The students learned this word during the first half of the semester and have been striving to use biomimicry in their Engineering Design class. The task is to create a toy with some surprising element while using biomimicry.

In order to study biomimicry and find inspiration, the students visited the Ishikawa Insect Museum earlier in the semester. There, they saw specimens of insects from around the world and also observed live insects native to Ishikawa. In The Butterfly Garden, students had the chance to walk among the butterflies as they flew around freely. Yuya even made a few butterfly friends who landed on him and would not leave! Some of the students were even brave enough to touch some of the insects as they observed them. They recorded videos in slow motion, sketched drawings, and took pictures. Hopefully, the students are no longer afraid of insects!

Returning to class, students have been working on incorporating biomimicry into the toys they are designing. With various elements of surprise, it’s been fun to see how the students are taking their observations and coming up with new designs and ideas. One group even put a lot of time into gluing and cutting sheets of paper to create their own paper honeycomb. The students are finishing up their prototypes this week and I can’t wait to see how their ideas turned out!

on him and would not leave! Some of the students were even brave enough to touch some of the insects as they observed them. They recorded videos in slow motion, sketched drawings, and took pictures. Hopefully, the students are no longer afraid of insects!

Anne Isobel Tan

2019年1月28日 バイオミミックリー

バイオミミックリー:自然界に見られる生態やアイデアを参考にして、デザインや解決法を生み出すこと。

今学期の前半、学生たちはこの言葉を習ってからバイオミミックリーをエンジニアリングデザインの授業で取り入れようと奮闘しています。課題はバイオミミックリーを活用してサプライズ要素のあるオモチャを作ることです。

バイオミミックリーの発想を得るために、学生たちは石川県ふれあい昆虫館へ出かけました。そこでは、世界中の昆虫の標本や、石川県に住む昆虫を実際に見て触れることができます。チョウの園では、自由に飛び回る蝶々の中を歩き回ることもできます。湧也さんにいたっては、体にとまってもまったく逃げないほど蝶と仲良くなりました!勇気のある学生は見るだけでなく、実際に昆虫を触って観察していました。その他にも、スローモーション撮影をしたり、スケッチをしたり、写真を撮っていました。昆虫と触れ合って、愛着が湧いたかもしれませんね。

教室に戻ってからは、学生はバイオミミックリーをオモチャに取り入れるデザイン作りをしました。サプライズ要素と一口に言っても色々な形があるので、学生がそれぞれ観察した内容を活かした新しいデザインやアイデアを生み出すのを見るのが面白かったです。中には紙を切り貼りして蜂の巣を作った学生もいました。今週でプロトタイプは完成予定なので、どのようにアイデアが形になるのか見るのが楽しみです!

アン・イソベル・タン

Hello, it's Jonathan the camera guy. Today, I would like to introduce this week's activity in the Engineering Design class. You can read more about Engineering Design here. It is the course where students use design thinking and engineering skills to make things for society. This week, we are building robots using Lego Mindstorms. Lego Mindstorms is a platform for robots that can be programmed and built using Lego blocks, motors, gears, sensors, tires, etc.

This week's Engineering Design class was divided into two parts. In the first part, students were given a list of challenges to program their robot; such as "turn exactly 90 degrees", "move forward and bring back a box" or "move along a fixed path." Mindstorms has a visualized programming interface, and users can program their robot simply by connecting orders on a computer and uploading them to the robot. Students could do the challenges in any order they wished. There was much trial and error. However, students completed the challenges one by one thanks to Mindstorms' user-friendly interface.

The second part was more interactive. The goal was to build and program a robot to fight Sumo wrestling style. Students were given 45 minutes to build and program their robot. Afterwards, they would hold a single elimination tournament. Students quickly began preparing their robots for battle. Many students added weapons to the front, while some worked on reworking the tires. 45 minutes passed in no time, and many students rushed to finish up their programs. Students could not control the robots after the battle started and they had to predict and program their robots as best they could. Students completed their robots and the tournament began.

It was interesting to see the individual strategies each student came up with for exterior and movement. Some students programmed their robot to advance forward, while others took a more "clever" approach and programmed their robot to back off to the side and flank the opponent. You can see a couple of the battles in the video below. As you can see, things do not always go as planned. The robot that won the tournament looks innocent without any added weaponry. However, its secret is in the tire mechanism. The builder explained that working with the gear ratio of the motor and tires, he was able to create a robot that moves slow but powerfully. After the tournament, students gave a presentation on their robot and about what they would do differently next time.

I asked the students about the class and many answered that they enjoyed it. It was an intense schedule, but a fulfilling one. Ogawa sensei, who is in charge of the class, explained that Mindstorms is a perfect way to prepare students for more complex programming and robot building in the future. This technology can be utilized to create robots for manufacturing lines, rescue robots, etc. in the future. There is a distinct muscle in the brain for programming robots the way you wish them to move and I believe this class was a fun and effective way to tap into that field. Thanks for watching. See you next time.

Jonathan

2018年11月1日 戦うロボット

こんにちは、ジョナサンです。今日は今週のエンジニアリングデザインの授業内容を紹介したいと思います。エンジニアリングデザインは学生がデザインシンキングや、ものづくりの技術を使って社会に役に立つものを作ることを学ぶ科目です。今週はLEGO Mindstormsを使ってロボットの製作をしました。LEGO Mindstormsはロボットのプラットフォームで、ブロック、モーター、ギア、センサー、車輪などを使ってロボットを組み立て、プログラミングを使って動かすことができます。

今週の授業は2つのパートがありました。前半では、「90度回転する」「前進して箱を掴み取る」「設定された道を進む」など、いくつかの課題が提示され、学生は達成すべくロボットのプログラミングに取り組みました。Mindstormsのプログラミングは視覚的にわかりやすいインターフェースなので、ユーザーはパソコン上で命令をつなぎ合わせることによってロボットの動きを設定することができます。学生は好きな順番で課題に取り組む事ができました。Mindstormsに挑戦するのは初めての1年生でしたが、直感的なインターフェースのおかげで試行錯誤しつつも、ひとつずつ課題をこなしていました。

後半はもっとインタラクティブな活動でした。課題は相撲形式で戦うロボットの製作およびプログラミングです。学生には製作時間45分が与えられ、その後、勝ち抜き形式のトーナメントが行われました。学生の中には、ロボットの正面に武器となる突起物を作る学生や、車輪周りを改造する学生もいました。作業に熱中していると45分はあっという間に過ぎ、最後の1分までプログラミングを急ぎました。試合が始まると学生はロボットを操作することはできなくなるので、試合の展開を予想しながらプログラミングを組む必要がありました。全員のロボットが完成し、いよいよトーナメントが始まりました。

学生によってロボットの見た目や、動きの戦術が多種多様で、見応えのある試合がたくさんありました。前進して相手を押し出すための動きをプログラミングした学生もいれば、後方へ下がって相手をやり過ごしてから側面を突く頭脳プレイを見せる学生もいました。いくつかの試合の動画を載せました。見てわかるように、なかなか計画通りにいかないものです。優勝したロボットは一見武器もついておらず平凡ですが、秘密は車輪周りにあります。製作者によると、ギア比を変えることによってゆっくり進むがパワフルなマシンを作れるとのことです。大会後は各学生が自分のロボットの解説と、改善すべき点を紹介していました。

学生に授業の感想を聞くと好意的な返答がたくさんありました。作業量が多く、ハードスケジュールだったが、充実感があったようです。担当のオガワ先生に聞いたところ、「Mindstormsはもっと複雑なプログラミングやロボット製作の導入として最適で、この技術は製作ラインのロボットや、人命救助ロボットなどに応用できる」と話してくれました。ロボットを思うように動かすには独特の知識とスキルがあるという風に感じました。この授業はその分野への導入として、非常に有効だったと思います。それでは、またお会いしましょう。

Hello, it's Jonathan the camera guy. Today, I would like to introduce this week's activity in the Engineering Design class. You can read more about Engineering Design here. It is the course where students use design thinking and engineering skills to make things for society. This week, we are building robots using Lego Mindstorms. Lego Mindstorms is a platform for robots that can be programmed and built using Lego blocks, motors, gears, sensors, tires, etc.

This week's Engineering Design class was divided into two parts. In the first part, students were given a list of challenges to program their robot; such as "turn exactly 90 degrees", "move forward and bring back a box" or "move along a fixed path." Mindstorms has a visualized programming interface, and users can program their robot simply by connecting orders on a computer and uploading them to the robot. Students could do the challenges in any order they wished. There was much trial and error. However, students completed the challenges one by one thanks to Mindstorms' user-friendly interface.

The second part was more interactive. The goal was to build and program a robot to fight Sumo wrestling style. Students were given 45 minutes to build and program their robot. Afterwards, they would hold a single elimination tournament. Students quickly began preparing their robots for battle. Many students added weapons to the front, while some worked on reworking the tires. 45 minutes passed in no time, and many students rushed to finish up their programs. Students could not control the robots after the battle started and they had to predict and program their robots as best they could. Students completed their robots and the tournament began.

It was interesting to see the individual strategies each student came up with for exterior and movement. Some students programmed their robot to advance forward, while others took a more "clever" approach and programmed their robot to back off to the side and flank the opponent. You can see a couple of the battles in the video below. As you can see, things do not always go as planned. The robot that won the tournament looks innocent without any added weaponry. However, its secret is in the tire mechanism. The builder explained that working with the gear ratio of the motor and tires, he was able to create a robot that moves slow but powerfully. After the tournament, students gave a presentation on their robot and about what they would do differently next time.

I asked the students about the class and many answered that they enjoyed it. It was an intense schedule, but a fulfilling one. Ogawa sensei, who is in charge of the class, explained that Mindstorms is a perfect way to prepare students for more complex programming and robot building in the future. This technology can be utilized to create robots for manufacturing lines, rescue robots, etc. in the future. There is a distinct muscle in the brain for programming robots the way you wish them to move and I believe this class was a fun and effective way to tap into that field. Thanks for watching. See you next time.

Jonathan

2018年11月1日 戦うロボット

こんにちは、ジョナサンです。今日は今週のエンジニアリングデザインの授業内容を紹介したいと思います。エンジニアリングデザインは学生がデザインシンキングや、ものづくりの技術を使って社会に役に立つものを作ることを学ぶ科目です。今週はLEGO Mindstormsを使ってロボットの製作をしました。LEGO Mindstormsはロボットのプラットフォームで、ブロック、モーター、ギア、センサー、車輪などを使ってロボットを組み立て、プログラミングを使って動かすことができます。

今週の授業は2つのパートがありました。前半では、「90度回転する」「前進して箱を掴み取る」「設定された道を進む」など、いくつかの課題が提示され、学生は達成すべくロボットのプログラミングに取り組みました。Mindstormsのプログラミングは視覚的にわかりやすいインターフェースなので、ユーザーはパソコン上で命令をつなぎ合わせることによってロボットの動きを設定することができます。学生は好きな順番で課題に取り組む事ができました。Mindstormsに挑戦するのは初めての1年生でしたが、直感的なインターフェースのおかげで試行錯誤しつつも、ひとつずつ課題をこなしていました。

後半はもっとインタラクティブな活動でした。課題は相撲形式で戦うロボットの製作およびプログラミングです。学生には製作時間45分が与えられ、その後、勝ち抜き形式のトーナメントが行われました。学生の中には、ロボットの正面に武器となる突起物を作る学生や、車輪周りを改造する学生もいました。作業に熱中していると45分はあっという間に過ぎ、最後の1分までプログラミングを急ぎました。試合が始まると学生はロボットを操作することはできなくなるので、試合の展開を予想しながらプログラミングを組む必要がありました。全員のロボットが完成し、いよいよトーナメントが始まりました。

学生によってロボットの見た目や、動きの戦術が多種多様で、見応えのある試合がたくさんありました。前進して相手を押し出すための動きをプログラミングした学生もいれば、後方へ下がって相手をやり過ごしてから側面を突く頭脳プレイを見せる学生もいました。いくつかの試合の動画を載せました。見てわかるように、なかなか計画通りにいかないものです。優勝したロボットは一見武器もついておらず平凡ですが、秘密は車輪周りにあります。製作者によると、ギア比を変えることによってゆっくり進むがパワフルなマシンを作れるとのことです。大会後は各学生が自分のロボットの解説と、改善すべき点を紹介していました。

学生に授業の感想を聞くと好意的な返答がたくさんありました。作業量が多く、ハードスケジュールだったが、充実感があったようです。担当のオガワ先生に聞いたところ、「Mindstormsはもっと複雑なプログラミングやロボット製作の導入として最適で、この技術は製作ラインのロボットや、人命救助ロボットなどに応用できる」と話してくれました。ロボットを思うように動かすには独特の知識とスキルがあるという風に感じました。この授業はその分野への導入として、非常に有効だったと思います。それでは、またお会いしましょう。

It's Ise from the Science and Technology department. Today I would like you to join me on a day at Hakusanroku campus.

In the morning, we gathered to discuss details of the Engineering Design class in the afternoon. Today's class was the student's mid-term report of the prototyping process. The final presentation date is two weeks from now. We debated how to support the students during this period.

After the meeting, I worked on a personal engineering design project of my own: improving the cleaning staff's working experience. This morning I built a bottle holder to attach to their tool cart. Currently, there is no space to put drinks or cellphones and the staff members do not want to put them with the cleaning utensils. I made the bottle holder from plywood, which I cut of using the laser cutter. The cleaning staff were extremely happy and I am considering making more for the remaining three carts.

After lunch, it was time for the Engineering Design class. The students gave presentations on their project's prototype and received advice from teachers and other students. Many of the students were nervous during the preparation time at the beginning of the class. However, everyone completed his or her presentation without any problems. There were many things students could not anticipate before actually creating the prototypes. I believe that they are beginning to understand the complexity of monozukuri.

We continued improving the prototypes based on the advice given. Each group divided its members depending on their strengths to increase efficiency.

After school, students worked on either the extracurricular activity Rube Goldberg machine (pitagora switch), or personal projects. It seems like they are living a fulfilling life at the campus. I hope students utilize the campus's facility fully to expand their monozukuri ability.

Ise Taisei

国際理工学科の伊勢です。今日は私の白山麓キャンパスの一日についてお伝えします。

まず、午前中は授業準備の打ち合わせです。午後からのエンジニアリングデザインの授業にむけて、改めてどのように指導していくか確認しています。今日の授業では、プロトタイプ製作の中間発表があり、2週後には最終発表です。発表までの流れについて、学生へのサポートの仕方などを検討しました。

その後、個人的に進めているエンジニアリングデザイン活動として、清掃担当の方の作業改善のため、清掃用具カートに取り付けられるボトルホルダー製作を行いました。カートには飲み物や携帯電話などを置くのに良いスペースがなく、清掃用具にあまり触れない場所に置きたいという要望がありました。ボトルホルダーはレーザー加工機でベニヤ板をカットして製作しました。実際に取り付けたところ、非常に喜んで頂けました。他にも3台カートがあるそうで、追加の製作も検討しています。

午後はエンジニアリングデザインの授業です。プロトタイプ製作途中の状態で発表を行い、教員や他の学生からの改善提案を受けます。授業の初めに発表準備では、学生は緊張している様子でしたが、無事に発表を終えました。やはり作ってみないと気付かないことも多く、一筋縄ではいかないものづくりの難しさを感じているようでした。

改善提案を踏まえてプロトタイプ製作を続行しました。班の中でもそれぞれの得意分野を活かし、適切に役割分担して作業に取り組んでいました。

放課後には、クラブ活動のRube Goldberg machine(ピタゴラスイッチ) 製作、自主的なものづくり活動などを行い、充実したキャンパスライフを送っているようでした。このものづくりの環境を学生に最大限に活用してもらい、技術力を高めて欲しいと思います。

伊勢 大成

It's Ise from the Science and Technology department. Today I would like you to join me on a day at Hakusanroku campus.

In the morning, we gathered to discuss details of the Engineering Design class in the afternoon. Today's class was the student's mid-term report of the prototyping process. The final presentation date is two weeks from now. We debated how to support the students during this period.

After the meeting, I worked on a personal engineering design project of my own: improving the cleaning staff's working experience. This morning I built a bottle holder to attach to their tool cart. Currently, there is no space to put drinks or cellphones and the staff members do not want to put them with the cleaning utensils. I made the bottle holder from plywood, which I cut of using the laser cutter. The cleaning staff were extremely happy and I am considering making more for the remaining three carts.

After lunch, it was time for the Engineering Design class. The students gave presentations on their project's prototype and received advice from teachers and other students. Many of the students were nervous during the preparation time at the beginning of the class. However, everyone completed his or her presentation without any problems. There were many things students could not anticipate before actually creating the prototypes. I believe that they are beginning to understand the complexity of monozukuri.

We continued improving the prototypes based on the advice given. Each group divided its members depending on their strengths to increase efficiency.

After school, students worked on either the extracurricular activity Rube Goldberg machine (pitagora switch), or personal projects. It seems like they are living a fulfilling life at the campus. I hope students utilize the campus's facility fully to expand their monozukuri ability.

Ise Taisei

国際理工学科の伊勢です。今日は私の白山麓キャンパスの一日についてお伝えします。

まず、午前中は授業準備の打ち合わせです。午後からのエンジニアリングデザインの授業にむけて、改めてどのように指導していくか確認しています。今日の授業では、プロトタイプ製作の中間発表があり、2週後には最終発表です。発表までの流れについて、学生へのサポートの仕方などを検討しました。

その後、個人的に進めているエンジニアリングデザイン活動として、清掃担当の方の作業改善のため、清掃用具カートに取り付けられるボトルホルダー製作を行いました。カートには飲み物や携帯電話などを置くのに良いスペースがなく、清掃用具にあまり触れない場所に置きたいという要望がありました。ボトルホルダーはレーザー加工機でベニヤ板をカットして製作しました。実際に取り付けたところ、非常に喜んで頂けました。他にも3台カートがあるそうで、追加の製作も検討しています。

午後はエンジニアリングデザインの授業です。プロトタイプ製作途中の状態で発表を行い、教員や他の学生からの改善提案を受けます。授業の初めに発表準備では、学生は緊張している様子でしたが、無事に発表を終えました。やはり作ってみないと気付かないことも多く、一筋縄ではいかないものづくりの難しさを感じているようでした。

改善提案を踏まえてプロトタイプ製作を続行しました。班の中でもそれぞれの得意分野を活かし、適切に役割分担して作業に取り組んでいました。

放課後には、クラブ活動のRube Goldberg machine(ピタゴラスイッチ) 製作、自主的なものづくり活動などを行い、充実したキャンパスライフを送っているようでした。このものづくりの環境を学生に最大限に活用してもらい、技術力を高めて欲しいと思います。

伊勢 大成

Matsushita from the science and technology department here. Today, I would like to give you a brief look into our Engineering Design class. The first semester is ending; and students are working actively to finish their project.

Since the second half of this semester, students are working in groups of three. First, they discussed inconveniences and problems within their studies, everyday life, and methods of communication. Next, they designed ways to solve them.

Now, students are creating prototypes of their solution. Not only do they use paper, pens, tape and magnets to create simple prototypes, but different tools and material such as the handsaw for woodwork, 3D printer, sticker cutting, compact motherboards and sensors to realize their ideas. In addition to what they learned in the class, they are applying knowledge and skill that they have accumulated from Compute Skills, afterschool activities, and personal projects. However, this knowledge and skill is never enough. During the process, there are many mistakes and things they do not know yet. When this happens, students revise their strategy by asking teachers or learning from trial-and-error. That is the spirit of conscious prototyping.

I am very excited for the final presentation where they will display their creation/user experience.

Omihito Matsushita

国際理工学科の松下です。今日は白山麓キャンパスで担当しているエンジニアリングデザインの授業の一コマをお伝えします。前学期も終盤に差し掛かり学生たちの活動も、より活発になってきました。

今学期後半からは、学生たちは3グループに分かれて活動しています。自分たちの学習や生活、情報共有の在り方など、身の回りで不便であったり問題だと思うことを話し合い、それらを解決するための課題に取り組んでいます。

現在はグループで考えたアイデアをカタチにする、プロトタイプ製作をしているところです。簡易的なプロトタイプに使用する紙やペン、テープやマグネットはもちろん、ハンドツールによる木工作業、3Dプリント、レーザー加工、ステッカーカッティング、マイコンボードとセンサーなど、アイデアに合わせて異なるツールと材料を使い分けてカタチづくりに臨んでいます。これらのプロトタイピングツールはこの授業で学んだことだけでなく、コンピュータスキルズや放課後の自主活動等で、これまで学んだことも応用されています。とはいえ、まだまだ限られたスキルと知識の中での作業に、分からないことがあったり、失敗することもあります。その時は、作るために必要なことを先生たちに更に教わったり、自分たちで試行錯誤をしながら、ひと工夫を施そうと試みています。まさに作りながら考えるプロトタイピング精神です。

今後どのようなカタチに発展し、どのようなユーザー体験を生み出していくのか。最終発表会が楽しみです。

松下臣仁

Matsushita from the science and technology department here. Today, I would like to give you a brief look into our Engineering Design class. The first semester is ending; and students are working actively to finish their project.

Since the second half of this semester, students are working in groups of three. First, they discussed inconveniences and problems within their studies, everyday life, and methods of communication. Next, they designed ways to solve them.

Now, students are creating prototypes of their solution. Not only do they use paper, pens, tape and magnets to create simple prototypes, but different tools and material such as the handsaw for woodwork, 3D printer, sticker cutting, compact motherboards and sensors to realize their ideas. In addition to what they learned in the class, they are applying knowledge and skill that they have accumulated from Compute Skills, afterschool activities, and personal projects. However, this knowledge and skill is never enough. During the process, there are many mistakes and things they do not know yet. When this happens, students revise their strategy by asking teachers or learning from trial-and-error. That is the spirit of conscious prototyping.

I am very excited for the final presentation where they will display their creation/user experience.

Omihito Matsushita

国際理工学科の松下です。今日は白山麓キャンパスで担当しているエンジニアリングデザインの授業の一コマをお伝えします。前学期も終盤に差し掛かり学生たちの活動も、より活発になってきました。

今学期後半からは、学生たちは3グループに分かれて活動しています。自分たちの学習や生活、情報共有の在り方など、身の回りで不便であったり問題だと思うことを話し合い、それらを解決するための課題に取り組んでいます。

現在はグループで考えたアイデアをカタチにする、プロトタイプ製作をしているところです。簡易的なプロトタイプに使用する紙やペン、テープやマグネットはもちろん、ハンドツールによる木工作業、3Dプリント、レーザー加工、ステッカーカッティング、マイコンボードとセンサーなど、アイデアに合わせて異なるツールと材料を使い分けてカタチづくりに臨んでいます。これらのプロトタイピングツールはこの授業で学んだことだけでなく、コンピュータスキルズや放課後の自主活動等で、これまで学んだことも応用されています。とはいえ、まだまだ限られたスキルと知識の中での作業に、分からないことがあったり、失敗することもあります。その時は、作るために必要なことを先生たちに更に教わったり、自分たちで試行錯誤をしながら、ひと工夫を施そうと試みています。まさに作りながら考えるプロトタイピング精神です。

今後どのようなカタチに発展し、どのようなユーザー体験を生み出していくのか。最終発表会が楽しみです。

松下臣仁

Learning to process metal

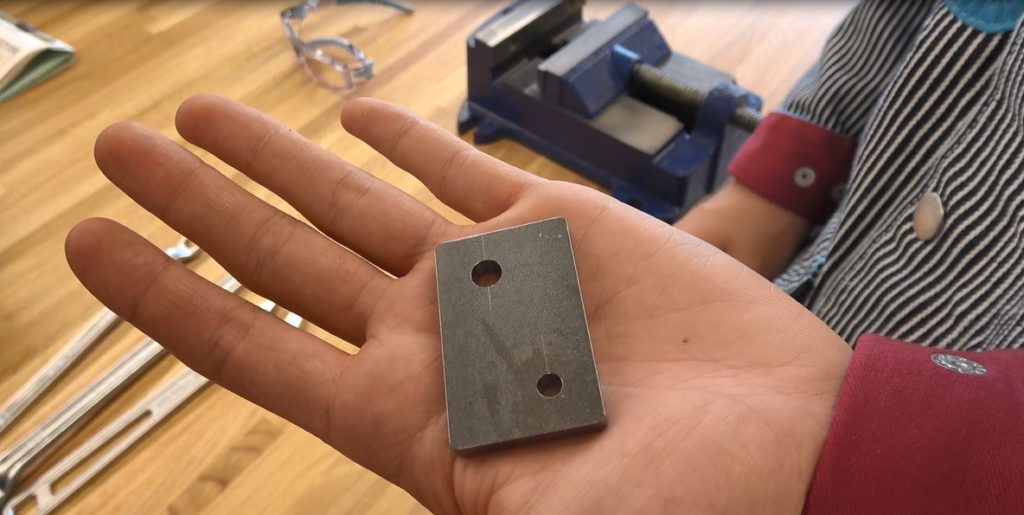

In today's Engineering Design, we learned how to use some of the tools for prototyping. Making a prototype is an important process in the problem-solving process. The class was divided into two groups. One group learned how to use the 3D printer, while the other group learned how to process metal in the Maker Studio. Students used the handsaw, drill, and many other tools to make the final product in picture three. Then, we connected all the metal tablets into a chain. The chain would not work if any of the tablets were manufactured incorrectly. However, as you can see in picture four, they were a perfect match! It's nice to have an end result that you can see and feel good about after all that hard work. I hope to show you more of the 3D printer group in the future. Stay tune.

Jonathan April 26, 2018

Learning to process metal

In today's Engineering Design, we learned how to use some of the tools for prototyping. Making a prototype is an important process in the problem-solving process. The class was divided into two groups. One group learned how to use the 3D printer, while the other group learned how to process metal in the Maker Studio. Students used the handsaw, drill, and many other tools to make the final product in picture three. Then, we connected all the metal tablets into a chain. The chain would not work if any of the tablets were manufactured incorrectly. However, as you can see in picture four, they were a perfect match! It's nice to have an end result that you can see and feel good about after all that hard work. I hope to show you more of the 3D printer group in the future. Stay tune.

Jonathan April 26, 2018